Quality,

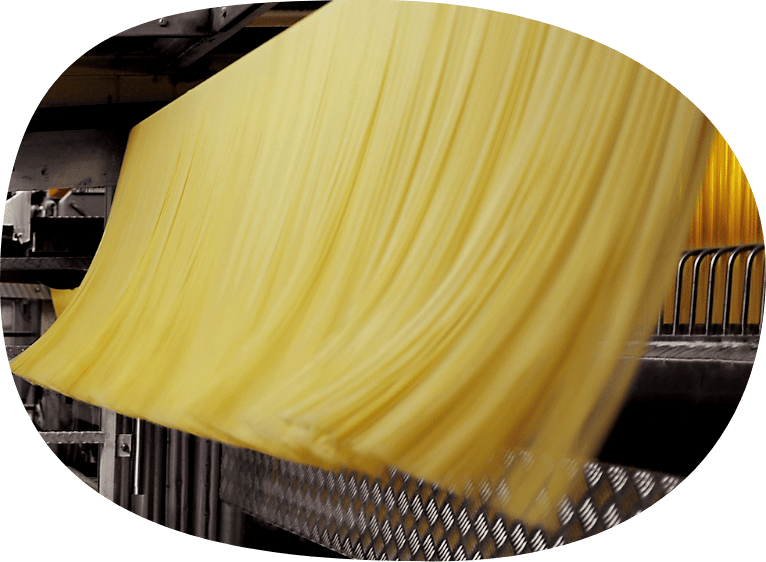

Our pasta is produced using high quality semolina from 65% wheat cultivated and milled in Italy and 35% durum wheat cultivated in EU and non-EU countries and milled in Italy.

Every stage of the production process is rigorously monitored, in order to ensure that our high standards of quality and hygiene are met.

Quality and care have always been at the heart of Divella’s production values and is a legacy that is enacted with pride, throughout each generation.

Food safety standards in the EU are considered some of the most stringent in the world. At Divella, we see this as a reflection of the needs of our

Customers and their expectation that we ensure compliance with every element of food safety, including traceability and transparency.

While customer satisfaction is the focal point of our daily operations at Divella, there is a set of principles embedded within the DNA of our company, that we simply will

not compromise on.

The cornerstone of our philosophy of corporate social responsibility, is worker health and safety. We understand the far-reaching impact that complacency on these issues can have, on the communities that we operate in.

This philosophy extends to the impact that our practices have on the environment, ensuring every decision that we make, is guided by the principles of sustainable practices and responsible resource management.

Through these practices, we aim to ensure that future generations of Divella customers, inherit a world that is as bountiful and breathtaking as the one we cherish today.